WeldFab’s diverse production capabilities enable us to manufacture a broad spectrum of parts for all types of industries. Our sheet metal fabrication process leverages our extensive industry experience as well as cutting-edge technology to ensure that our customers receive their deliveries on time and at cost-effective prices.

WeldFab engineers use SolidWorks as their 3D modeling software. This allows them to import many 3D models (ProE, Inventor, Step, Iges and etc). 3D models can be validated using Dr ABE software. Dr ABE simulates bending sequence and tooling required to get formed parts completed successfully the first time. These models are then passed on to Quality for inspection.

Sheet Metal

WeldFab works on sheet metal ranging from 0.020" to 1.00" in thickness, depending on the material. Our standard sheet metal materials include:

- Steel - CR, HRP&O

- Aluminum

- Stainless Steel

- Galvanized Steel

- Galvannealed Steel

What We Do

Here is a list of the most common jobs we perform and the equipment we use to perform them. If you don’t see the equipment or procedure you need, contact us to get a more exhaustive list and explore your options.

Brake Press

- (1) Amada HG 1003 ATC Auto Tool Load Brake

- (1) Amada EG6013 Electric Brake

- (2) Amada HG 2204 8 Axis CNC Brake

Laser Cutting

- (1) Amada LCG 3015 AJ Fiber 4000 Watt 60" x 120"

- (2) Amada F1 4000 watt 60” x 120”

Can cut steel, aluminum, and stainless steel up to 3/4” thick.

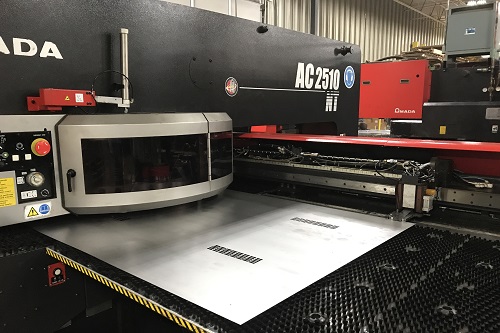

Turret Punching

- (1) Amada AC 2510 NT Turret Punch

Capable of punching up to 1/4” material with auto load & unload 50” x 96”.

Laser-Turret Combo

- (1) Amada Apelio 1500 watt

Capable of punching 1/4” thick 50” X 144” with reposition.

WeldFab welding with the latest Miller Welders including 6 Continuum 500 Welding Systems and 1 Miller Dynasty 280 DX amongst other equipment.

Robot Welding

- (2) Miller PerformArc 350S [66” Swing Diameter 3’ Height]

- (1) Miller PerformArc 2200SS [6 Axis, Fully Integrated with a Head and Tailstock Positioner on each side of the Robot. Head/Tail Distance 120”. 2200 lb Payload per side. Servo Positioners at each station for part rotation, robot controlled.]

Other Welding

- CD stud welding

- Arc stud welding

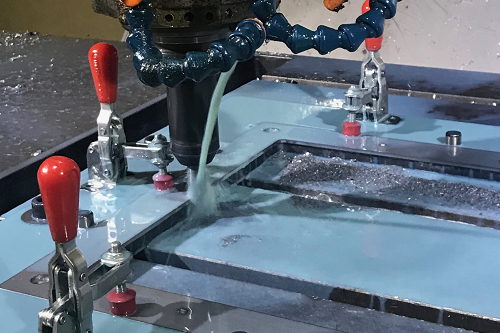

Machining Centers

- (3) Fadal vertical machining centers with 16 station tool changers and rigid tapping with 60” x 30” table size

CNC Lathe

- (2) Miyano with live tooling and bar feed to 1.375” Diameter

Other

- Drill Pressing

Sawing

- (2) Marvel Saws with NC programming

Capable of cutting multiple pieces at one time.

CNC Mandrel Tube Bending

- (1) 1.500” Outside Diameter Round and 1.000” Square Tube

- (1) 3.000” Outside Diameter Round and 2.000” Square Tube

ISO 9001:2015 Registration

- (1) Virtek laser scanner for flat pattern measuring

- (1) Romer Absolute 7535SI with PolyWorks software

Portable measuring arm with fully certified and integrated RS4 laser scanner designed for faster-than-ever 3D data capture across a range of surfaces and applications.

Quality manual and documentation program.

Shearing

- (1) Wysong NC Hydraulic Shear

Capable of shearing up to 1/4” thick x 10’ long sheet material.

Pem Insertion

- (3) 8 ton Pemserter machines with auto feed to 3/8” hardware

- (6) 6 ton Pemserter machines

Other Capabilities

Tube Rolling

Deburring Grinds

Rivnut Insertion

And Many More

Facility Equipment/Features

We are located at 180 James St., Slinger, WI 53086 in a newer 50,000-square-foot facility and are equipped with:

Crane, Cradle or Side Forklift 5000 lbs/ lift capability

- (2) Dock Levelers

Ground Level loading